Instrument Page

The conceptual design of the instrument is driven by the WEAVE science requirements, as defined by the Science Team, and translated to technical requirements by the Project and Instrument Scientists. At the time of writing the requirements call for a dual-beam spectrograph with the following characteristics:

| Borderless table | |||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Specification | Requirement | Goal |

|---|---|---|

| Field of view diameter | 2 degrees | 2 degrees |

| MOS multiplex | 800 | 1000 |

| Atmospheric dispersion compensation | 0.4-1.0 µm, 50oZD | 0.37-1.0 µm, 60oZD |

| MOS fibre aperture | >=1.2" | 1.5" |

| Open shutter efficiency (1 hour observations) | 70% | 90% |

| Wavelength coverage | 400-950nm | 370-1000nm |

| Spectral resolution (full simultaneous coverage) | 5000 | 5000 |

| Spectral resolution (reduced coverage) | 20000 | 20000 |

| Stray light as function of faintest target | <1% | |

| Blue system efficiency | 20% | 25% |

| Red system efficiency | 25% | 30% |

| Multi-IFU multiplex | 10 | 30 |

| Multi-IFU FOV | 9" x 9" | 9" x 12" |

| Multi-IFU spaxel size | 0.8" | >1.2" |

| Single IFU FOV | 3' x 3' | |

| Single IFU spaxel size | 2.5" | Inner 1", outer 2.5" |

The philosophy behind the construction of WEAVE is to keep it simple but effective. Thus the design exploits the use of COTS (Commercial Off-The Shelf) components which not only reduces project costs and risks but provides an attractive solution for maintaining the instrument throughout its lifecycle.

The Positioner

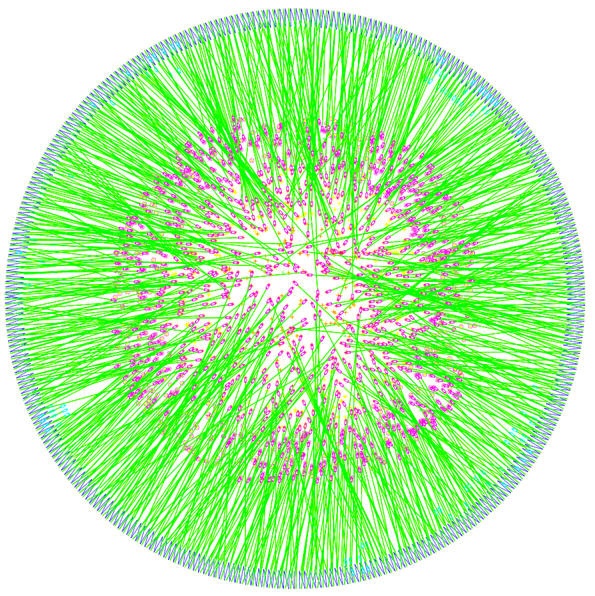

Pick-and-place technology will be used to position the fibre buttons onto a plate using a commercially available X-Y gantry. A computer simulation shows the complexity of weaving 920 fibres to acquire their targets. Each green line represents a single fibre and the purple beads are the magnetic buttons. In this particular example there are 8300 fibre crossings.

At the edge of the field are the fibre retractors (originally designed for GYES) that tension and protect the individual fibres. Each retractor holds four fibres and the buttons are seated at the entrance to the retractors as illustrated in the following pictures.

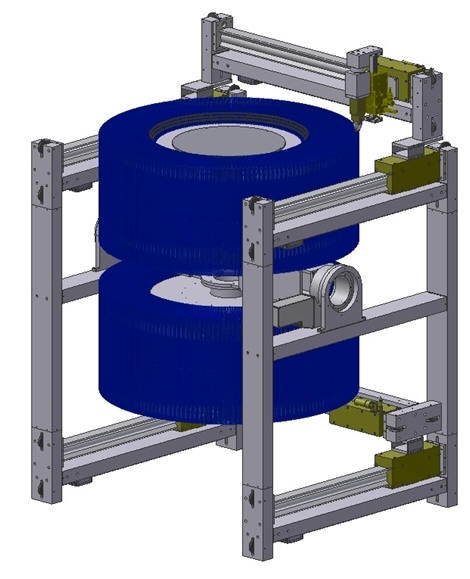

The fibre positioning mechanism is a twin-based system of fibres, retractors and buttons etc. The arrangement is s uch that 1000 fibre-assemblies are positioned at each end of the rotating assembly also known as the tumbler. This fits inside a gantry with a robotic gripper that places the buttons on the plate. This arrangement allows for reconfiguration of the top plate whilst the bottom plate is used for observing.

The Spectrograph

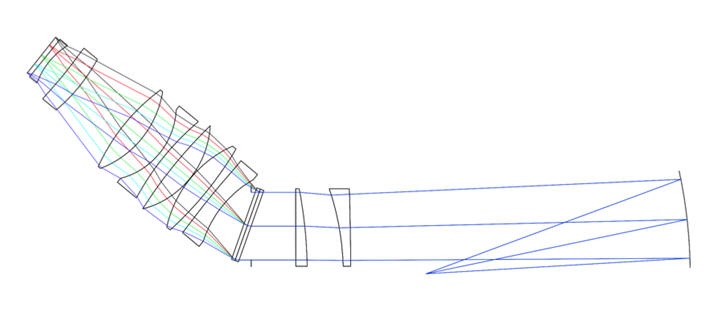

Fibres from the positioner are fed to the dual-beam spectrograph which incorporates a dichroic at ~600nm and has two volume phase holographic gratings. The spectrograph will be housed in GHRIL.